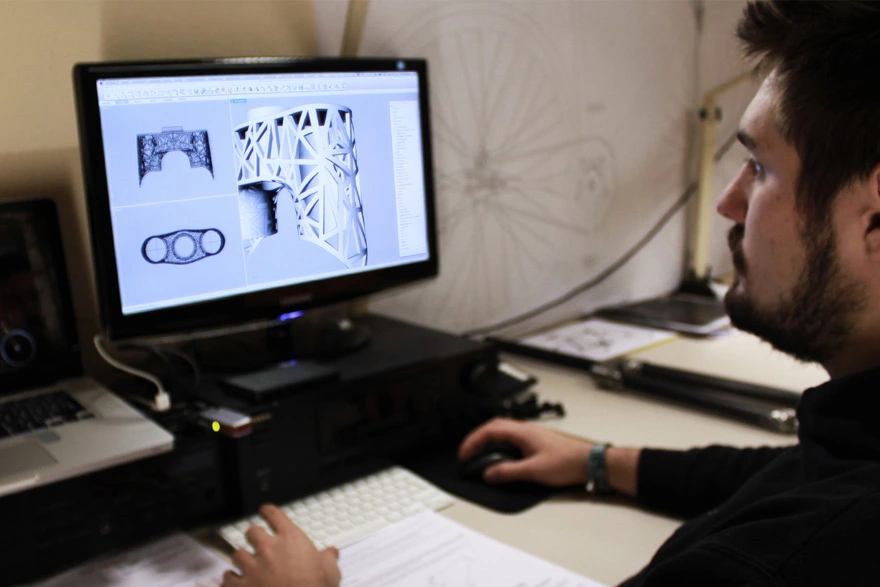

Photos by Simon Markhof

With the help aerospace engineers at EADS, Somerset, UK-based

Charge Bikes

have refined and expanded their 3D-printed dropout production since we

first came across them last August

, as evidenced by a

new vid

from last week. However, German IDer

Ralf Holleis

does them one better with the

VRZ 2 Track

bicycle, developed under the

VORWaeRTZ

moniker. (Further details on Holleis's practice are scant; from what I can determine, he's connected to the equally mysterious

designlab coburg

.)

The making-of video is actually for the VRZ 1, which dates back to January of 2012; no word on any new developments beyond the prototype of the VRZ 2 with a belt drive. In other words, I can't imagine this is going into production, however limited, any time soon.

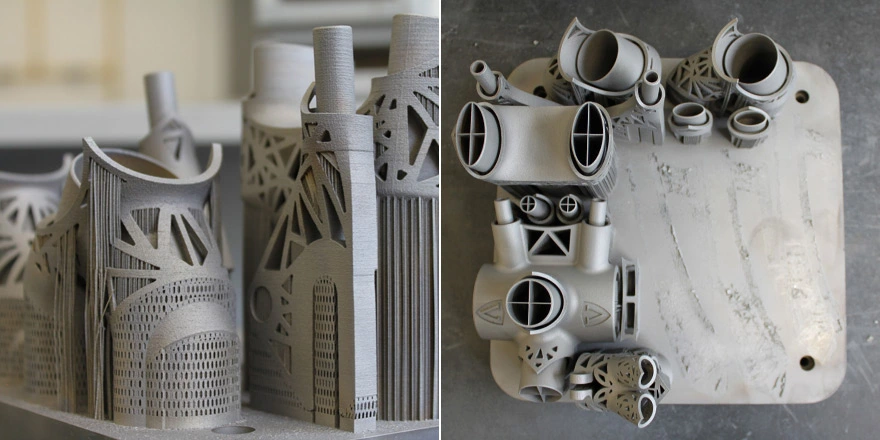

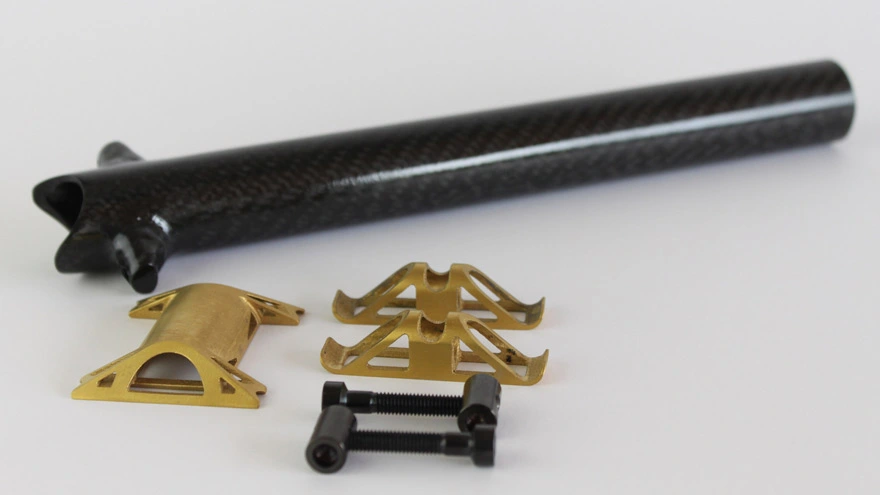

The lugs, fresh off the build platform

Unlike the Charge dropouts, the lugs of the VRZ 2 Track are produced with a proprietary process called

LaserCUSING

. I'm not going to attempt to explain the

purported advantages of 'cusing' over sintering

(even my survey of

other methods for 3D printing metals

was a stretch), but interested parties can peruse a technical overview of the technology

here (PDF)

.

Each one is like a little sculpture...

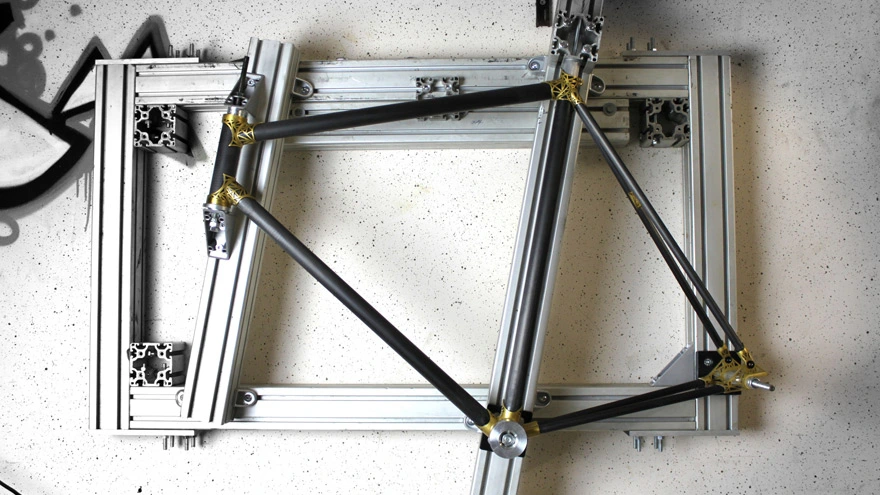

The jig is up

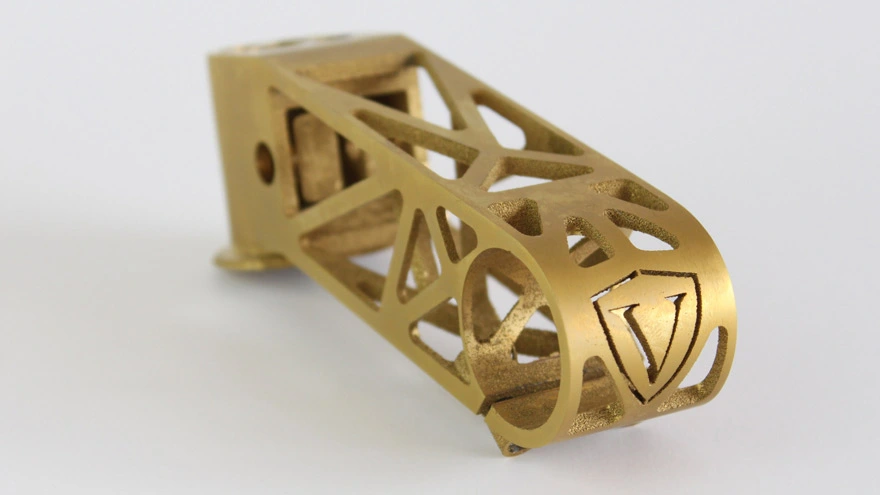

The brake bridge might be my favorite...

The truss-like stem

Also digging the seatpost

After

Todd McLellan

?

Bonus video: Holleis has also applied his additive manufacturing expertise to the holiday spirit as well, as his latest project is a series of

3D-printed Christmas cookies

:

Hat-tip to

Tangram Design